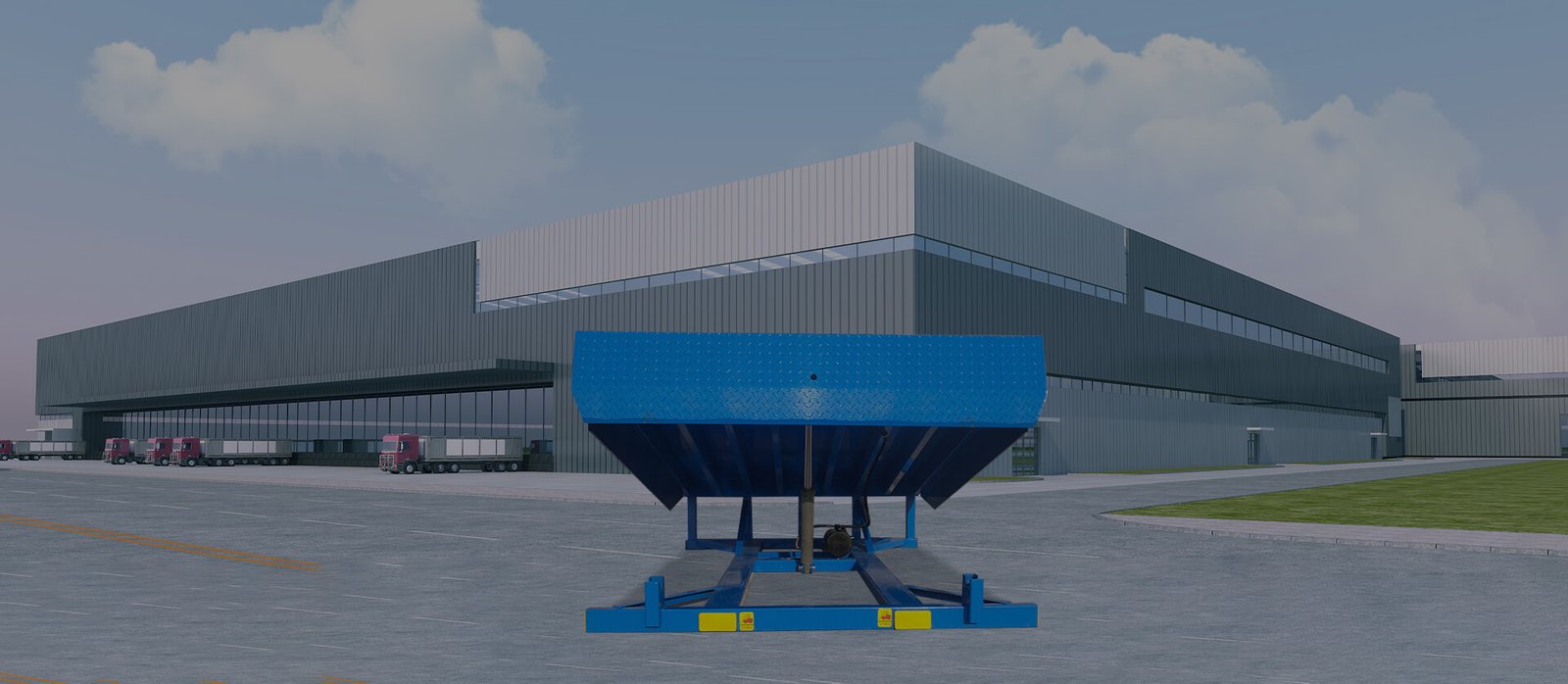

10 years of focus on the manufacture and sales of lifts

Hydraulic Loading Dock Leveler DL6 DL8 DL10

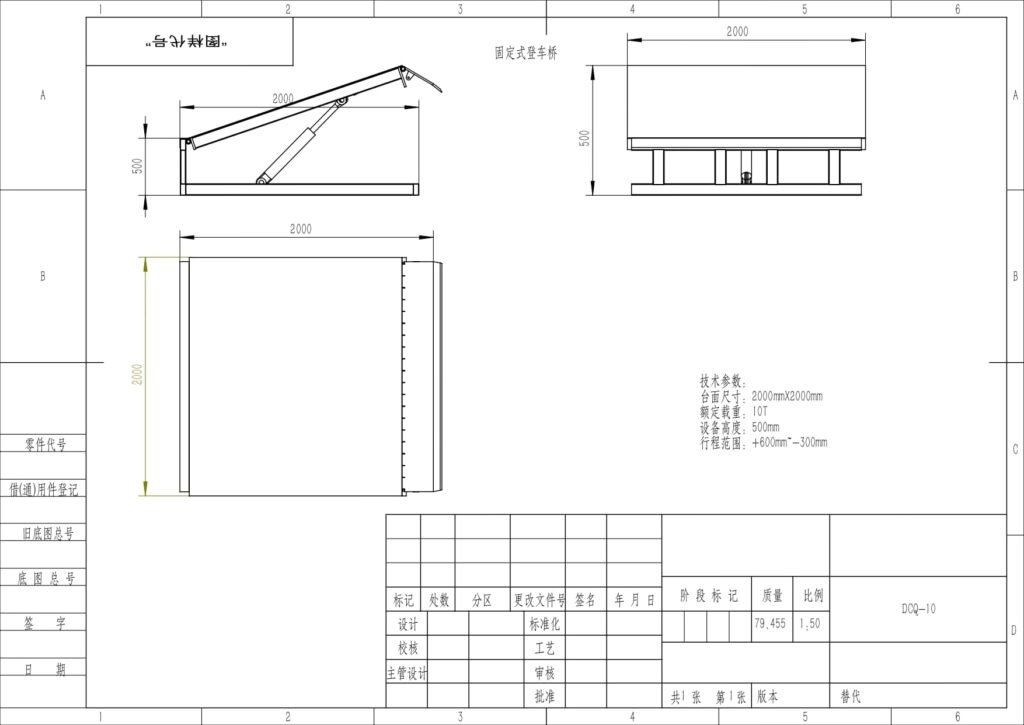

PRODUCT PARAMETERS

The workbench frame must use welded Baosteel rectangular tubes with a 6mm steel plate surface for structural strength and safety.

All rotating shafts require quenching/tempering treatment to enhance hardness and durability.

Hydraulic systems shall integrate Dayu cylinders with German Dessef seals and emergency cut-off valves for leak-proof operation.

Electrical controls must adopt ≤24V safety voltage with dual interlock mechanisms to prevent operational errors.

Modular design and international certifications (ISO/CE) are mandatory for maintenance accessibility and compliance.

Description

Structural Aspect

The main frame of the workbench is welded from rectangular tubes produced by Shanghai Baosteel Group, featuring high strength, excellent stability, and lightweight design. The working surface is covered with a 6mm thick steel plate, ensuring both comprehensive structural integrity and enhanced operational safety. The spline shafts used in the rotating components connected to the supports undergo quenching and tempering treatment, which not only ensures surface hardness but also significantly improves overall mechanical performance, thereby extending the service life of the platform.

Hydraulic System

The hydraulic cylinders are manufactured by Hebei Dayu Hydraulic Cylinders, known for their reliability and durability. The integrated pump station incorporates precision-ground hydraulic cylinders, combining check valves, relief valves, and solenoid valves into a compact design to minimize leakage while maintaining performance. Additionally, a cut-off valve is equipped to allow platform lowering in the event of a power outage. All sealing elements utilize German-made “Dessef” seals (original imported) for superior sealing performance.

Electrical System

The electrical system offers the following advantages:

Safe voltage operation to ensure personnel safety

Interlocking functionality to effectively prevent human errors during control operations.

Product Model:

| Model/Parameter | DL8 | DL10 | DL12 |

|---|---|---|---|

| Tabletop | 2000mm*2500mm | 2000mm*2500mm | 2000mm*2500mm |

| Rated Load | 8 tons | 8 tons | 8 tons |

| Own Height | 600mm | 600mm | 600mm |

| Lifting Stroke | 400mm up and 300mm down | 400mm up and 300mm down | 400mm up and 300mm down |

| Tongue plate size | 2000mm*400mm | 2000mm*400mm | 2000mm*400mm |

| Pit Size | 2500mm*2030mm*610mm | 2500mm*2030mm*610mm | 2500mm*2030mm*610mm |

| Main frame of tabletop | 100*50*4mm | 100*50*4mm | 100*50*4mm |

| Workbench | 6mm checkered steel plate | 6mm checkered steel plate | 6mm checkered steel plate |

| Tongue plate | 14mm checkered plate | 14mm checkered plate | 14mm checkered plate |

| Under frame column | 80*40*4mm | 80*40*4mm | 80*40*4mm |

| Base frame | Using 10# channel steel | Using 10# channel steel | Using 10# channel steel |

| Control method | Using 24V safety control | Using 24V safety control | Using 24V safety control |

| Pump station | 1.1KW/380V/50HZ | 1.1KW/380V/50HZ | 1.1KW/380V/50HZ |

| Main cylinder | 70#*1 piece | 70#*1 piece | 70#*1 piece |

| Tongue plate cylinder | 40#*1 piece | 40#*1 piece | 40#*1 piece |

| Side skirt | 2mm steel plate | 2mm steel plate | 2mm steel plate |

| Oil tank | 8 liters | 8 liters | 8 liters |

| Hydraulic oil pipe | Rubber tube | Rubber tube | Rubber tube |

| Hydraulic oil | Hydraulic oil | Hydraulic oil | Hydraulic oil |

| Anti-collision block | 300*180*100mm | 300*180*100mm | 300*180*100mm |

| Equipment finish | Sky blue/dark gray | Sky blue/dark gray | Sky blue/dark gray |

Video:

Some drawings:

Delivery to customers:

FAQs

As an ISO 9001-certified manufacturer of elevation equipment, we specialize in engineered lifting solutions including:Scissor Lifts (EN 1570 compliant, 2-18m lift height),Boom Lifts (Articulating/Telescopic, 360° rotation capability),Fixed Scissor Platforms (Customizable up to 30T static load),Vehicle Turntables (Hydraulic drive, Ø5-15m configurations),Dock Levelers (Fixed/Mobile types, EN 1398:2017 certified),Guided Freight Elevators (Mast-guided rail system, 500-3000kg capacity)

We primarily utilize sea freight and rail transport as our primary logistics channels, with optimized routes covering major global ports and inland terminals.

We provide client-exclusive engineering drawings and will commence production only after obtaining your final approval through our ECO (Engineering Change Order) validation process.

Our ordering process initiates with precise product specification confirmation through CAD drawing approvals, followed by a 30% advance payment via secure international transfer channels (TT/LC/SWIFT accepted), which triggers production commencement within 24 hours of payment verification. The remaining 70% balance must be settled prior to bill of lading issuance, ensuring full compliance with INCOTERMS 2020 regulations and seamless cargo release from origin ports.

All products are guaranteed for one year